The Packaging Rap

SKS Bottle & Packaging Newsletter

Canning

June 2016

Home gardens provide healthy fruits and vegetables, and canning allows them to be enjoyed year-round. To put it simply, canning is using heat to kill any microorganisms and stop enzymes that could spoil food. Boiling water bath canning and pressure canning are two options that both remove air from the jar and create an airtight seal to keep food fresh. SKS Bottle & Packaging carries many styles and sizes of jars that could be used to can fruits, vegetables, red meats, poultry, pickles, and relishes.

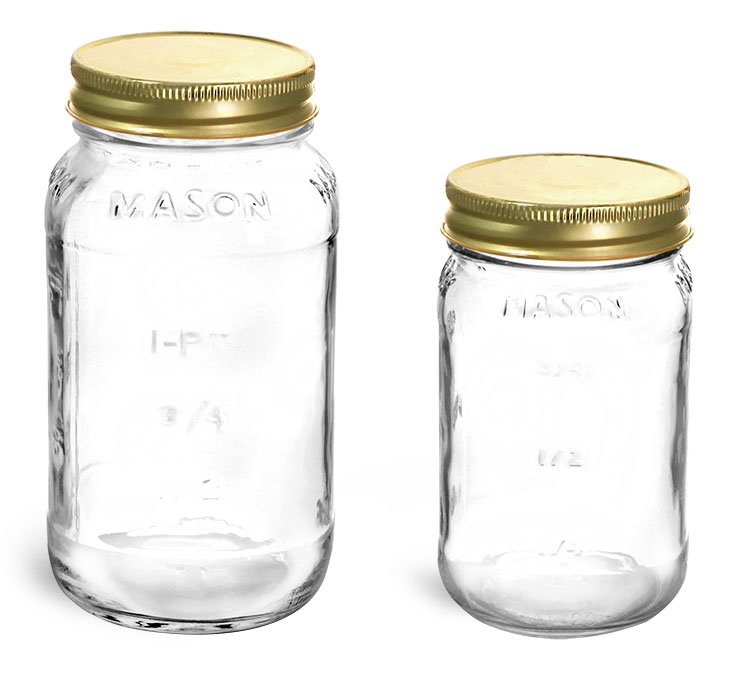

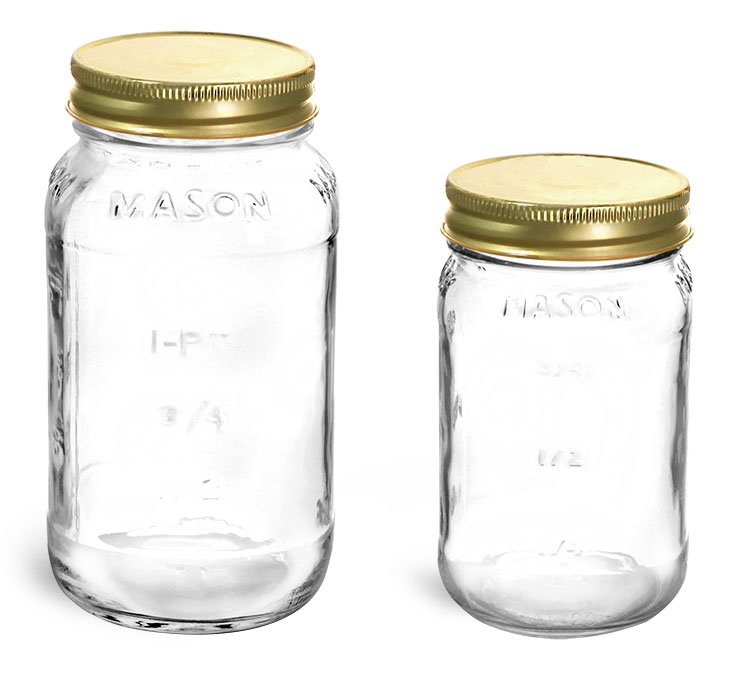

Mason Jars

Mason jars are the most common style of canning jars, which SKS offers in 16 oz and 25 oz sizes. Both sizes have a 70G neck finish that can accommodate gold, silver, black, white, and red plastisol lined metal caps.

Glass Economy Jars

Glass economy jars are another classic option that come in 8 oz, 16 oz, and 32 oz sizes. The 58/400 neck finish of the 8 oz jar allows for compatibility with plastisol lined gold caps and white caps. The 16 oz and 32 oz sizes feature a 70G neck finish like the mason jars, which are compatible with the same gold, silver, black, white, and red plastisol lined caps.

Glass Paragon Jars

The SKS glass paragon jars range from 1 oz to 16 oz sizes and feature a narrow, tall body, while the line of continuous thread straight sided glass jars are wider and shorter, ranging in size from 1 oz to 32 oz. With such a large size selection there is something to suit nearly all needs, making these jars are a great option for an entire line of product. Both the clear glass jar and paragon jar product lines have common neck finishes making it easy to find a compatible cap for all sizes.

Glass Straight Sided Jars with Lug Finish

SKS also offers another line of clear glass straight sided jars that feature lug finishes. These jars come in 7.75, 9, 12, and 16 oz sizes. The 7.75 oz and 9 oz feature 70/2030 lug finishes, while the 12 oz and 16 oz sizes feature 82/2030 lug finishes. Pair any of these four jars with gold, silver, or red lug caps.

Glass Jelly Jars

Available in 1.25 oz or 8 oz sizes, a jelly jar or jam jar could be a great option for canning jam, jelly and even relishes, pickles or vegetables. The smaller jam jar could be paired with a gold plastisol lined lug cap, while the larger 8 oz jam jar could be paired with a gold, silver, white, red, or black metal 70G plastisol lined caps. The line of clear glass wide mouth jars offered by SKS could also be a great option for a jelly or jam jar. These jars will hold smaller quantities of food from 60 ml to 200 ml and can be paired with a variety of compatible lug caps.

Clear Glass Hexagon Jars

SKS offers clear glass hexagon jars in sizes ranging from 1.5 oz to 9 oz, and oval hexagon jars from 1.5 oz to 12 oz. Both styles of the hexagon jars have lug finishes and can be paired with gold, silver, black, or red metal caps depending on the size of the jars. Use the cap codes page to find which caps go with the jar that suits your needs!

Preparing the Containers

For safety, jars should always be cleaned before beginning the canning process. Some foods with a shorter processing time do require jars to also be sterilized. However for, vegetables, meats, and fruits processed in a pressure canner, or foods processed more than ten minutes in a boiling water canner, sterilization of jars is not required. When sterilization is required, submerge jars in a boiling water canner, with hot water one inch above the rims of the jars. Jars should be kept hot until filled. If your jars don’t require sterilization they can be put on a complete regular cycle in the dishwasher and kept closed inside, or put in simmering water until filling with the food to be preserved.

Helpful Hints for Canning

To make sure food doesn’t spoil, there are many important factors to keep in mind throughout the canning process. First of all, make sure to use the correct canning method according to the recipe you are following. Generally, boiling water canners are used for high-acid foods such as fruits, pickled vegetables, and relishes, while pressure canners are more appropriate for low acid foods like meat, seafood, and vegetables. To keep vegetables as fresh as possible, they should be washed well and canned right after picking. For safety, be sure to always use up-to-date recipes with correct processing times, pressures, and make sure there is appropriate headspace in the jar. Headspace is the area measured from the inside of the cap to the top of the liquid and generally ranges from ¼” for foods like jams and jellies, to 1 ¼” for low acid foods. Always follow the recipe for how much headspace to leave because all food has different air content, which will affect expansion. Too much headspace will create a lower vacuum, and too little headspace may force food under the cap, both resulting in a weak seal. Before putting caps on the jars, wipe the rims of the jars clean to ensure a tight seal and remove air bubbles with a plastic or wooden tool to prevent discoloration, spoilage, or changes in flavor. When fastening caps, the sealing agent should be touching the rim of the jar in order to create a tight seal. Do not reuse caps when canning because they will not seal to the jars properly after the first use, ultimately causing the food in the jars to spoil. After processing the jars according to the recipe, do not tighten the caps as this may cause the seals to fail. Allow the jars to cool for 12-24 hours.

Choose one of the many glass jars SKS stocks to suit your canning needs and make your summer garden last all year. There are many styles and sizes of jars with a variety of compatible caps available. As always, be sure to test your product with our containers to ensure proper performance.

Packaging Tip

Torque

Torque is the amount of force it takes to secure or remove a closure to a container. The amount of torque that is applied, has an impact on the seal created between the closure and the bottle. Many believe that the tighter a closure is applied, the less chance for leakage. However, when using too much pressure to secure a closure to a container, it can increase the possibility of leakage. Over-torquing can cause some points on the cap to have more pressure than others, which could create a weak seal. On the other hand, not securing the closure tightly enough can cause leakage, or even for the cap to come off entirely. Although you should always test your products to ensure compatibility, visit this information page for a chart outlining exactly how much torque should be used to properly apply and remove closures.

Product of the Month

Clear Glass Liquor Bottles

SKS recently added a 1 liter clear glass bottle that is only compatible with 28/350 tamper evident caps. This is a beneficial feature to provide the end user with comfort in knowing the product has not been altered. Pair these bottles with an unlined black ribbed closure and a custom label to further brand your product. The black tamper evident caps that could be paired with these bottles features a frangible ring at the base of the cap skirt. Fasten the cap onto the bottle and the ring will break away from the cap, staying under the lip on the bottle. Once this connection is broken, the components cannot be reattached. These bottles could be a great option for packaging liquors, wines, or oils.

Shop All Packaging

Shop All Packaging Glass Containers

Glass Containers Plastic Containers

Plastic Containers Metal Containers

Metal Containers Cardboard Containers

Cardboard Containers Industrial Containers

Industrial Containers Caps / Closures

Caps / Closures Shrink Bands

Shrink Bands Design Custom Labels

Design Custom Labels Subscribe & Save Orders

Subscribe & Save Orders Shop By Industry

Shop By Industry Custom Packaging

Custom Packaging Pallet Qty Packaging

Pallet Qty Packaging SKS Direct Wholesale

SKS Direct Wholesale Packaging Equipment

Packaging Equipment Help/Info

Help/Info New Products

New Products Promotions

Promotions Newsletters

Newsletters Combo Kit Deals

Combo Kit Deals Product Closeouts

Product Closeouts Recently Back In Stock

Recently Back In Stock